Frequently Asked Questions

Turbocharger FAQ:

Choosing a Turbocharger

In order to make an informed decision when

purchasing an aftermarket turbo, the consumer needs

to avail themselves of the different types of turbos

first. To this end, we will discuss the various

types of turbos on the market. These are just the

basics of turbo information though. Please do not

confuse this as the main source for turbo

information as there are many other factors to an

informed turbo choice such as compressor maps,

matching the turbo to your displacement, etc. For

the best advice, please consult an experienced turbo

vendor and/or your tuner.

A regular turbo is, in essence, a pump that forces air into your intake system. The end result is a denser air charge that will produce more power vs. naturally aspired vehicles. The only downside is that more power produces more heat, and the engine’s internal components must be properly suited towards turbo charging. Upgrading this unit to a larger one is the easiest route in terms of time, trouble, and expense. Common upgrades for all turbocharged Subaru models include the VF-30/34/22 and 16/18/20G.

A twin scroll turbo is designed to be used on an equal length exhaust set-up. By internal turbo design and having all the exhaust gases enter the turbo at the same time, this allows the turbo to spool faster vs. an equally sized regular turbo. This is a very important point as many people are confused by the marketing hype of twin scroll set-ups. When comparing a twin scroll turbo that will flow say 500 cfm vs. a normal 500 cfm turbo, the twin scroll should see full boost sooner. So if there are two suitably sized turbochargers, with one being twin scroll and one regular, the twin scroll unit may be your best choice if you do not mind the extra exhaust expense and prefer faster spooling.

This type of turbocharger requires more expense than a simple upgrade though. The biggest concern is the use of an equal length header, proper uppipe design, and the possible use of a different oil pan to accommodate the new twin scroll exhaust piping. Quirt Crawford of Crawford Performance recently did some testing on a GT32 twin scroll turbo Legacy to test the theory about the importance of exhaust flow to a twin scroll unit. When he switched from the correct equal length header and uppipe to a traditional unequal length header and normal uppipe, he saw degradation in turbo response by 750 RPM. This should be word to the wise to anyone who thinks they can avoid the expense of the correct exhaust components and still see the quicker spooling benefits of a twin scroll turbo.

Another consideration is the change in exhaust tone. An equal length header required in a twin scroll set-up sounds entirely different than an OEM or aftermarket unequal length header. To fans of the familiar boxer rumble, equal length headers are just not an option. It may sound silly, but for many, this reason alone is enough to keep them from buying a twin scroll turbo.

A rotated mount turbo is any turbo that’s physical size prevents it from fitting in the stock location and must be mounted at a slightly different angle. Most of the turbos that fall into this category are of the larger variety. Many require custom piping, a front mount intercooler, external wastegates, custom tuning, tumble generator valve deletes, and other technical or expensive upgrades to support it. Most would consider this type of turbo to be outside the scope of the average do it yourself person and should be farmed out to a professional or at least utilize one of the kits supplied by various manufacturers.

As well, many feel that when going this route, strong consideration should be given to fully built motor, or at the very least, forged pistons. Rotated mount turbos produce large amounts of power and though there is no magic horsepower number for switching to forged internals, the larger rotated mount set-ups seem to be commonly used on built motors.

Twin turbos on Subarus are rarely seen. Though there are no official numbers, one would guess that the amount in the United States could be counted on one hand. The reason for the rarity is due to cost, customization, and tuning that is involved with this type of set-up. This is definitely something one would want to leave to a professional. It requires enormous amounts of fabrication, careful planning, and time to execute in a reliable fashion. Aside from the mounting, tuning is also critical, as the turbos tend to fight each other to see which one can push the most air into the engine. This is especially true at higher boost levels and is something that takes a real professional to mechanically isolate and/or electronically tune.

Few Subaru modifications get the heart pumping as much as aftermarket turbos. This article will get down to the brass tacks to allow you to make an educated choice in what turbo specifications are and how to match them to your wishes.

The first step is to learn some terminology as it applies to turbos:

CHRA Center Housing Rotating Assembly. This is the internal part of the turbo from the bearing area between the two halves of the turbo shell to the main shaft and both blades.

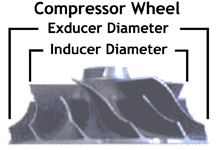

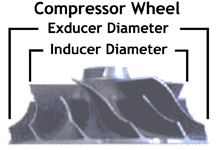

Compressor Inducer smaller diameter portion of the compressor blade.

Compressor Exducer larger diameter portion of the compressor blade.

Turbine Inducer larger diameter portion of the exhaust blade.

Turbine Exducer smaller diameter portion of the exhaust blade.

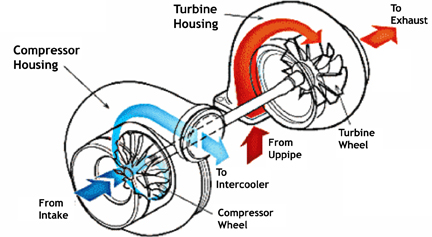

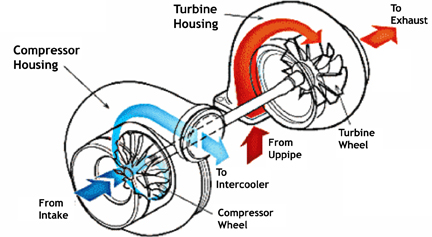

The main halves of the turbo shell draw most of the attention, but sadly, as with many things in life, these halves have many names depending on the source of information. Cold side/inducer/inlet/compressor/intake and hot side/exducer/outlet/turbine/exhaust are all the popular names attributed to each half. For the purposes of this article, we will refer only to the terms turbine and compressor.

Turbine is the complete wheel inside the turbine housing. Its purpose is to spin via exhaust gas, which in turn spins the compressor wheel.

Compressor complete wheel inside the compressor housing. Its purpose is to compress the intake charge on its way to the intercooler.

Compressor map X/Y plot of the compressor’s efficiency range. After mathematical calculations based on your vehicle and desires, you end up with a plot that is used to determine turbo suitability.

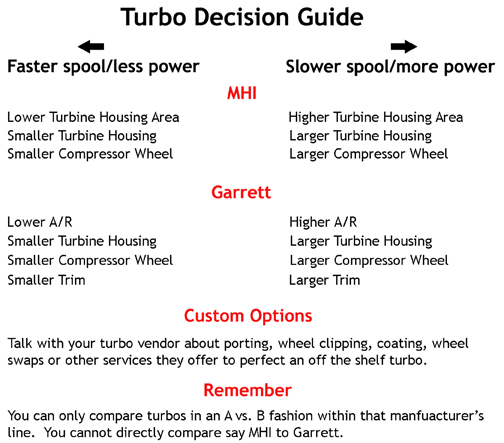

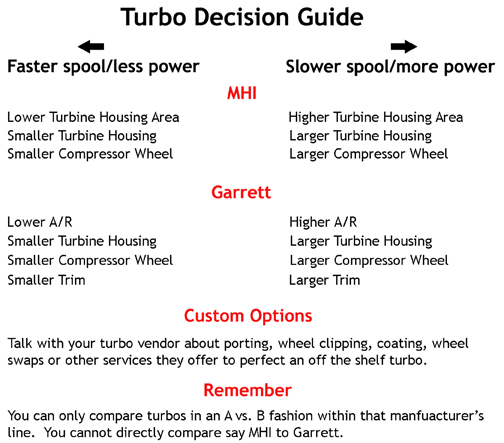

Trim relationship of the inducer and exducer of a given wheel. Compressor trim = (inducer²/exducer²) ×100. Turbine trim = (exducer²/inducer²) ×100. All measurements are in millimeters. You will end up with a trim of say .64 which will be expressed as a 64 trim wheel. In almost every case, advertised trim ratios reflect those of the compressor wheel vice the turbine wheel. In a perfect world, the higher trim numbers will produce more power and more lag while lower trim numbers will spool faster but produce less power. This is not always the case though as A/R plays a role in the manipulation of the airflow as well.

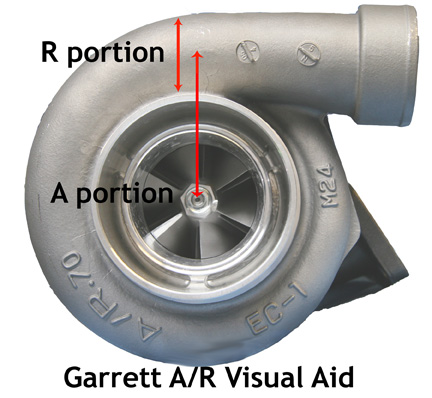

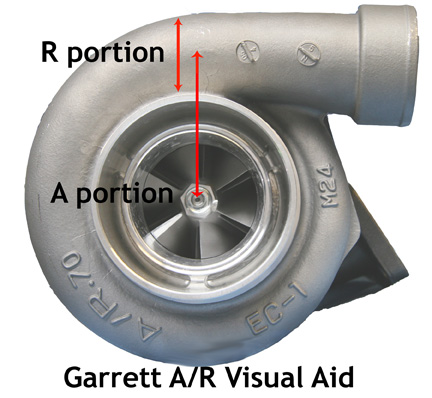

A/R Area/Radius Ratio. One way to envision the concept of the A/R ratio is to think of the way the turbine housing wraps around the turbo. Imagine it as cornucopia that wraps around the turbine. The A portion is the small end and its shape and size effects the force which exhaust gases hit the blades. The R portion is the distance from the center of the section area in the turbine housing at the 12 o’clock position to the center of the turbine shaft; the size, shape, and distance of travel all affect the ultimate turbine velocity. The A/R is then the ratio between the volume of the compressor where it discharges to the turbine to the distance to between the turbine shaft to the center of the 12 o’clock position. This is a summary of the definition as provided by Corky Bell.

Interestingly enough, the definition from Garrett is slightly different. The A portion is exactly the same as the below documented MHI THA. The R portion is the distance from the center of the section area in the turbine housing at the 12 o’clock position to the center of the A portion.

As to which definition is most correct, that’s anyone’s guess, but the definition is not so important as the concept of the ratios. The A/R can be applied to both the compressor and turbine housings. In most cases though, the compressor A/R has little effect on turbo performance, so it is not given. As to turbine A/R, the smaller number A/R will generate quicker spool, but less top end power and the higher A/R number will generate more power at the cost of slower spool. This holds true when comparing different A/R figures of the same sized turbine housing.

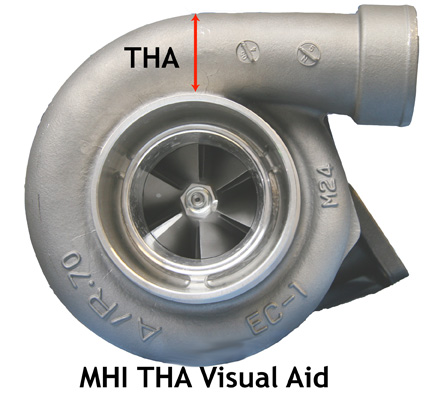

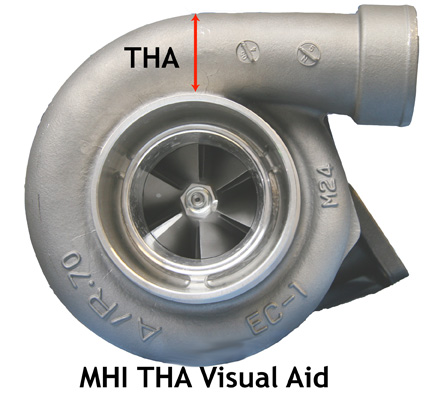

MHI Turbine Housing Area (THA) is the newly created term for the “A/R” of MHI turbos. While their measurement area differs slightly from the traditional A/R, the end result is similar whereas the smaller numbers spool faster with less top end and the larger numbers spool slower with more top end. This measurement is technically the area of the housing at the 12 o’clock position.

Wastegates internal or external devices designed to control boost. Both control boost levels by allowing exhaust gasses to bypass the turbine, which limits the boost created by the compressor. Internal units are a wastegate built on the turbo. External units are larger and bypass the internal unit to increase flow away from the turbine, though some turbos are externally designed and lack an internal wastegate. Though every turbo can benefit from an external wastegate, they really shine on larger turbos. Wastegates also need tuning to run effectively. The rule of thumb for wastegate tuning is to utilize a spring inside the wastegate that is 50% of the amount of boost you will run. If you exceed the 50% rule, you may run into wastegate creep or other issues.

Wastegate creep where the wastegate will start to open prematurely. As boost gets closer to the set level of the spring, the spring will begin to open the wastegate and slow spool time.

Boost creep when with the wastegate open, boost rises over target levels. This is normally seen at high RPMs or during cold weather. It is usually attributed to the wastegate being too small. Common fixes are tuning to combat the problem or wastegate enlargement. Case in point, the replacement of the VF39 with the VF43 on the STI; identical turbos, but the VF43 has a larger wastegate.

Boost spike or boost surge a brief period of uncontrolled boost, usually encountered in lower gears during the onset of boost. Typically spikes occur when the boost controller can’t keep up with the changing engine conditions. This can often be caused by improper turbo sizing.

Anti-surge ports ports in the compressor housing that permit excess air to pass through the compressor wheel and into the anti-surge ports. One may think of this as a “wastegate” on the compressor side. In essence, this moves the compressor’s surge line to the left as seen on a compressor map. These are generally only used on larger rotated mount turbos.

Boost threshold is the engine speed at which there is sufficient exhaust gas flow to generate positive manifold pressure, or boost.

Turbo lag the time delay of boost response after the throttle is opened when operating above the boost threshold engine speed.

Porting and Polishing grinds away excess material within the turbo. Since the housings are cast units, they can leave behind flashing from the cast process and tend to be flat walled. Porting and polishing smoothes the interior portions and knife edges inlets and outlets for more flow.

Clipping process of removing material from the edge of the turbine blades, usually at a 10 or 20 degree angle. This imparts more flow around the blades, increasing flow at the cost of a reduction in spool. Clipping gives you an apparent increase in A/R.

Now that we have the terminology out of the way, we are ready to discuss turbo manufacturers and their products. Most people who think of aftermarket turbos get overwhelmed by the sheer amount of turbos. To remove most of the mystery associated, remember one simple thing, there are only three turbo manufacturers: MHI, IHI, and Garrett. Yes, there are rogue set-ups that certain people have, but 99% of the turbos you see advertised are direct products or variants of the Big Three. We will now discuss each manufacturer and their nomenclature.

Ishikawajima-Harima Heavy Industries (IHI) manufactures around 30 different turbos. Nomenclature is based on VFXX. Example name: VF34. Unlike other manufacturers’ whose naming system refers to capability, IHI turbos are named according to date of origin. Since the origin dates are all purpose built units, their power capabilities are all over the spectrum within the numbering system.

IHI turbos are generally smaller than their aftermarket cousins and cannot be rebuilt. The flipside to this is that they are generally great daily driver turbos and many offer unique features such as twin scroll design or the use titanium components. As well, many of these turbos appeal to Japanese spec minded Subaru owners.

One downside to these turbos is the amazing lack of documentation. About the only information you can get on these turbos, if you are lucky, is the exhaust housing size. P11, P12, P14, P15, P18, P20, and P25 are the known available exhaust housings. As with their turbo number system, the numbers related to their creation date vs. flow capacity. Additionally, no compressor maps exist for IHI turbos.

Mitsubishi Heavy Industries (MHI) is the largest Japanese turbo manufacturer. Their turbos have been used for years with wonderful results on a variety of cars. They are based off of older technology, but are proven performers. They can be rebuilt and upgraded from one size to the next in most cases.

The nomenclature for MHI turbos is somewhat complicated, but is easily broken down into four parts:

Turbine housing: TD04 through TD08 are the most commonly used and these refer to sizes, lower numbers being smaller, higher numbers being bigger. The same rules apply for spool and power, lower numbers spooling faster with less power, higher numbers spooling slower with more power. The turbine housing may also have a letter modifier such as S, SH, H, etc. This modifier refers to the turbine wheel inside and is basically a non-factor.

Compressor housing: Same rules apply as to the turbine housing. Usually are matched to the turbine housing, therefore this data is not in the turbo name.

MHI Turbine Housing Areas: A/R equivalents of THA figures are 6 cm2 = 0.41 A/R, 7 cm2 = 0.49 A/R, 8 cm2 = 0.57 A/R, 9 cm2 = 0.65 A/R, 10 cm2 = 0.73 A/R, 11 cm2 = 0.81 A/R, 12 cm2 = 0.89 A/R. The equivalents given are meant for people to have one understanding of two different concepts. MHI uses THA to denote housing variances and their effect on spool/flow. Garrett uses the term A/R to do the same thing. However each use unique measurement points to do so. The equivalents given are just a way to stick to one standard for people who cannot grasp the two different concepts. Please note this figures are for MHI to MHI comparison and not MHI to Garrett comparison. A/R or THA are comparative measures within each manufacturer’s own line and cannot be used across manufacturer lines or against other turbine housing size lines. Each MHI housing has its own THA variants.

Compressor wheels: 16, 18, and 20, with higher numbers representing more flow. These may also A, B, C, G, or T modifiers. Modifiers can affect the number, height, and pitch of the blades, and whether all blades are full height or some are half blades, like the popular G model.

Example name: TD06H-20G 7 cm2 or housing size/mod.-compressor wheel size/mod. THA

Within reason, most of these components can be changed around so you can have smaller wheels in bigger housings or have a TD04 turbine with a TDO5 compressor. So the possible amount of MHI based turbo combinations is rather high.

The Garrett format for naming/sizing their turbos is the format of GTXaabbcccc. GT is the standard name for all Garrett turbos. The X position denotes any revision to the turbo and is optional. aa is turbine size and bb is compressor wheel size expressed in mm, with higher numbers representing more flow. cccc refers to special codes that are optionally used such as R for ball bearing. Detailed Garrett nomenclature decoding is available on Garrett’s website.

Example name: GT3076R or housing size/compressor wheel size/special code.

As with the MHI units, Garret components can be swapped around as well to the limits of their designs.

The “fourth option” is a hybrid turbo. Most hybrids are MHI or Garrett based, as IHI turbos only accept simple things like clipping, wheel swaps, etc. With regard to the other models though, one can utilize MHI and Garrett parts to create a hybrid within reason.

Now you should have a solid foundation to research which type, brand, and size of turbo will suit your needs. Remember that research is critical and you shouldn’t choose the “turbo of the month” as many seem to do. A 500HP capable turbo can be an absolute dog to drive in stop and go traffic. Likewise, a turbo with Insta-Spool® will not net you an 11 second time slip. Many of the features here are described as smaller = less power, fast boost and bigger = more power, slow boost. The same rules apply to turbos overall. The goal is to find a happy medium which will meet most of your desires.

This article should not your sole source of information though and you should consider the following additional research activities when considering an upgrade:

a. Compressor map plotting and interpretation (MHI and Garrett particularly)

b. Your tuner’s advice and experience

c. Your turbo vendor’s advice and experience

d. Corky Bell’s book "Maximum Boost: Design, Testing, and Installing Turbocharger Systems". Considered by many to be the Alpha and Omega of turbo information.

A regular turbo is, in essence, a pump that forces air into your intake system. The end result is a denser air charge that will produce more power vs. naturally aspired vehicles. The only downside is that more power produces more heat, and the engine’s internal components must be properly suited towards turbo charging. Upgrading this unit to a larger one is the easiest route in terms of time, trouble, and expense. Common upgrades for all turbocharged Subaru models include the VF-30/34/22 and 16/18/20G.

A twin scroll turbo is designed to be used on an equal length exhaust set-up. By internal turbo design and having all the exhaust gases enter the turbo at the same time, this allows the turbo to spool faster vs. an equally sized regular turbo. This is a very important point as many people are confused by the marketing hype of twin scroll set-ups. When comparing a twin scroll turbo that will flow say 500 cfm vs. a normal 500 cfm turbo, the twin scroll should see full boost sooner. So if there are two suitably sized turbochargers, with one being twin scroll and one regular, the twin scroll unit may be your best choice if you do not mind the extra exhaust expense and prefer faster spooling.

This type of turbocharger requires more expense than a simple upgrade though. The biggest concern is the use of an equal length header, proper uppipe design, and the possible use of a different oil pan to accommodate the new twin scroll exhaust piping. Quirt Crawford of Crawford Performance recently did some testing on a GT32 twin scroll turbo Legacy to test the theory about the importance of exhaust flow to a twin scroll unit. When he switched from the correct equal length header and uppipe to a traditional unequal length header and normal uppipe, he saw degradation in turbo response by 750 RPM. This should be word to the wise to anyone who thinks they can avoid the expense of the correct exhaust components and still see the quicker spooling benefits of a twin scroll turbo.

Another consideration is the change in exhaust tone. An equal length header required in a twin scroll set-up sounds entirely different than an OEM or aftermarket unequal length header. To fans of the familiar boxer rumble, equal length headers are just not an option. It may sound silly, but for many, this reason alone is enough to keep them from buying a twin scroll turbo.

A rotated mount turbo is any turbo that’s physical size prevents it from fitting in the stock location and must be mounted at a slightly different angle. Most of the turbos that fall into this category are of the larger variety. Many require custom piping, a front mount intercooler, external wastegates, custom tuning, tumble generator valve deletes, and other technical or expensive upgrades to support it. Most would consider this type of turbo to be outside the scope of the average do it yourself person and should be farmed out to a professional or at least utilize one of the kits supplied by various manufacturers.

As well, many feel that when going this route, strong consideration should be given to fully built motor, or at the very least, forged pistons. Rotated mount turbos produce large amounts of power and though there is no magic horsepower number for switching to forged internals, the larger rotated mount set-ups seem to be commonly used on built motors.

Twin turbos on Subarus are rarely seen. Though there are no official numbers, one would guess that the amount in the United States could be counted on one hand. The reason for the rarity is due to cost, customization, and tuning that is involved with this type of set-up. This is definitely something one would want to leave to a professional. It requires enormous amounts of fabrication, careful planning, and time to execute in a reliable fashion. Aside from the mounting, tuning is also critical, as the turbos tend to fight each other to see which one can push the most air into the engine. This is especially true at higher boost levels and is something that takes a real professional to mechanically isolate and/or electronically tune.

Few Subaru modifications get the heart pumping as much as aftermarket turbos. This article will get down to the brass tacks to allow you to make an educated choice in what turbo specifications are and how to match them to your wishes.

The first step is to learn some terminology as it applies to turbos:

CHRA Center Housing Rotating Assembly. This is the internal part of the turbo from the bearing area between the two halves of the turbo shell to the main shaft and both blades.

Compressor Inducer smaller diameter portion of the compressor blade.

Compressor Exducer larger diameter portion of the compressor blade.

Turbine Inducer larger diameter portion of the exhaust blade.

Turbine Exducer smaller diameter portion of the exhaust blade.

The main halves of the turbo shell draw most of the attention, but sadly, as with many things in life, these halves have many names depending on the source of information. Cold side/inducer/inlet/compressor/intake and hot side/exducer/outlet/turbine/exhaust are all the popular names attributed to each half. For the purposes of this article, we will refer only to the terms turbine and compressor.

Turbine is the complete wheel inside the turbine housing. Its purpose is to spin via exhaust gas, which in turn spins the compressor wheel.

Compressor complete wheel inside the compressor housing. Its purpose is to compress the intake charge on its way to the intercooler.

Compressor map X/Y plot of the compressor’s efficiency range. After mathematical calculations based on your vehicle and desires, you end up with a plot that is used to determine turbo suitability.

Trim relationship of the inducer and exducer of a given wheel. Compressor trim = (inducer²/exducer²) ×100. Turbine trim = (exducer²/inducer²) ×100. All measurements are in millimeters. You will end up with a trim of say .64 which will be expressed as a 64 trim wheel. In almost every case, advertised trim ratios reflect those of the compressor wheel vice the turbine wheel. In a perfect world, the higher trim numbers will produce more power and more lag while lower trim numbers will spool faster but produce less power. This is not always the case though as A/R plays a role in the manipulation of the airflow as well.

A/R Area/Radius Ratio. One way to envision the concept of the A/R ratio is to think of the way the turbine housing wraps around the turbo. Imagine it as cornucopia that wraps around the turbine. The A portion is the small end and its shape and size effects the force which exhaust gases hit the blades. The R portion is the distance from the center of the section area in the turbine housing at the 12 o’clock position to the center of the turbine shaft; the size, shape, and distance of travel all affect the ultimate turbine velocity. The A/R is then the ratio between the volume of the compressor where it discharges to the turbine to the distance to between the turbine shaft to the center of the 12 o’clock position. This is a summary of the definition as provided by Corky Bell.

Interestingly enough, the definition from Garrett is slightly different. The A portion is exactly the same as the below documented MHI THA. The R portion is the distance from the center of the section area in the turbine housing at the 12 o’clock position to the center of the A portion.

As to which definition is most correct, that’s anyone’s guess, but the definition is not so important as the concept of the ratios. The A/R can be applied to both the compressor and turbine housings. In most cases though, the compressor A/R has little effect on turbo performance, so it is not given. As to turbine A/R, the smaller number A/R will generate quicker spool, but less top end power and the higher A/R number will generate more power at the cost of slower spool. This holds true when comparing different A/R figures of the same sized turbine housing.

MHI Turbine Housing Area (THA) is the newly created term for the “A/R” of MHI turbos. While their measurement area differs slightly from the traditional A/R, the end result is similar whereas the smaller numbers spool faster with less top end and the larger numbers spool slower with more top end. This measurement is technically the area of the housing at the 12 o’clock position.

Wastegates internal or external devices designed to control boost. Both control boost levels by allowing exhaust gasses to bypass the turbine, which limits the boost created by the compressor. Internal units are a wastegate built on the turbo. External units are larger and bypass the internal unit to increase flow away from the turbine, though some turbos are externally designed and lack an internal wastegate. Though every turbo can benefit from an external wastegate, they really shine on larger turbos. Wastegates also need tuning to run effectively. The rule of thumb for wastegate tuning is to utilize a spring inside the wastegate that is 50% of the amount of boost you will run. If you exceed the 50% rule, you may run into wastegate creep or other issues.

Wastegate creep where the wastegate will start to open prematurely. As boost gets closer to the set level of the spring, the spring will begin to open the wastegate and slow spool time.

Boost creep when with the wastegate open, boost rises over target levels. This is normally seen at high RPMs or during cold weather. It is usually attributed to the wastegate being too small. Common fixes are tuning to combat the problem or wastegate enlargement. Case in point, the replacement of the VF39 with the VF43 on the STI; identical turbos, but the VF43 has a larger wastegate.

Boost spike or boost surge a brief period of uncontrolled boost, usually encountered in lower gears during the onset of boost. Typically spikes occur when the boost controller can’t keep up with the changing engine conditions. This can often be caused by improper turbo sizing.

Anti-surge ports ports in the compressor housing that permit excess air to pass through the compressor wheel and into the anti-surge ports. One may think of this as a “wastegate” on the compressor side. In essence, this moves the compressor’s surge line to the left as seen on a compressor map. These are generally only used on larger rotated mount turbos.

Boost threshold is the engine speed at which there is sufficient exhaust gas flow to generate positive manifold pressure, or boost.

Turbo lag the time delay of boost response after the throttle is opened when operating above the boost threshold engine speed.

Porting and Polishing grinds away excess material within the turbo. Since the housings are cast units, they can leave behind flashing from the cast process and tend to be flat walled. Porting and polishing smoothes the interior portions and knife edges inlets and outlets for more flow.

Clipping process of removing material from the edge of the turbine blades, usually at a 10 or 20 degree angle. This imparts more flow around the blades, increasing flow at the cost of a reduction in spool. Clipping gives you an apparent increase in A/R.

Now that we have the terminology out of the way, we are ready to discuss turbo manufacturers and their products. Most people who think of aftermarket turbos get overwhelmed by the sheer amount of turbos. To remove most of the mystery associated, remember one simple thing, there are only three turbo manufacturers: MHI, IHI, and Garrett. Yes, there are rogue set-ups that certain people have, but 99% of the turbos you see advertised are direct products or variants of the Big Three. We will now discuss each manufacturer and their nomenclature.

Ishikawajima-Harima Heavy Industries (IHI) manufactures around 30 different turbos. Nomenclature is based on VFXX. Example name: VF34. Unlike other manufacturers’ whose naming system refers to capability, IHI turbos are named according to date of origin. Since the origin dates are all purpose built units, their power capabilities are all over the spectrum within the numbering system.

IHI turbos are generally smaller than their aftermarket cousins and cannot be rebuilt. The flipside to this is that they are generally great daily driver turbos and many offer unique features such as twin scroll design or the use titanium components. As well, many of these turbos appeal to Japanese spec minded Subaru owners.

One downside to these turbos is the amazing lack of documentation. About the only information you can get on these turbos, if you are lucky, is the exhaust housing size. P11, P12, P14, P15, P18, P20, and P25 are the known available exhaust housings. As with their turbo number system, the numbers related to their creation date vs. flow capacity. Additionally, no compressor maps exist for IHI turbos.

Mitsubishi Heavy Industries (MHI) is the largest Japanese turbo manufacturer. Their turbos have been used for years with wonderful results on a variety of cars. They are based off of older technology, but are proven performers. They can be rebuilt and upgraded from one size to the next in most cases.

The nomenclature for MHI turbos is somewhat complicated, but is easily broken down into four parts:

Turbine housing: TD04 through TD08 are the most commonly used and these refer to sizes, lower numbers being smaller, higher numbers being bigger. The same rules apply for spool and power, lower numbers spooling faster with less power, higher numbers spooling slower with more power. The turbine housing may also have a letter modifier such as S, SH, H, etc. This modifier refers to the turbine wheel inside and is basically a non-factor.

Compressor housing: Same rules apply as to the turbine housing. Usually are matched to the turbine housing, therefore this data is not in the turbo name.

MHI Turbine Housing Areas: A/R equivalents of THA figures are 6 cm2 = 0.41 A/R, 7 cm2 = 0.49 A/R, 8 cm2 = 0.57 A/R, 9 cm2 = 0.65 A/R, 10 cm2 = 0.73 A/R, 11 cm2 = 0.81 A/R, 12 cm2 = 0.89 A/R. The equivalents given are meant for people to have one understanding of two different concepts. MHI uses THA to denote housing variances and their effect on spool/flow. Garrett uses the term A/R to do the same thing. However each use unique measurement points to do so. The equivalents given are just a way to stick to one standard for people who cannot grasp the two different concepts. Please note this figures are for MHI to MHI comparison and not MHI to Garrett comparison. A/R or THA are comparative measures within each manufacturer’s own line and cannot be used across manufacturer lines or against other turbine housing size lines. Each MHI housing has its own THA variants.

Compressor wheels: 16, 18, and 20, with higher numbers representing more flow. These may also A, B, C, G, or T modifiers. Modifiers can affect the number, height, and pitch of the blades, and whether all blades are full height or some are half blades, like the popular G model.

Example name: TD06H-20G 7 cm2 or housing size/mod.-compressor wheel size/mod. THA

Within reason, most of these components can be changed around so you can have smaller wheels in bigger housings or have a TD04 turbine with a TDO5 compressor. So the possible amount of MHI based turbo combinations is rather high.

The Garrett format for naming/sizing their turbos is the format of GTXaabbcccc. GT is the standard name for all Garrett turbos. The X position denotes any revision to the turbo and is optional. aa is turbine size and bb is compressor wheel size expressed in mm, with higher numbers representing more flow. cccc refers to special codes that are optionally used such as R for ball bearing. Detailed Garrett nomenclature decoding is available on Garrett’s website.

Example name: GT3076R or housing size/compressor wheel size/special code.

As with the MHI units, Garret components can be swapped around as well to the limits of their designs.

The “fourth option” is a hybrid turbo. Most hybrids are MHI or Garrett based, as IHI turbos only accept simple things like clipping, wheel swaps, etc. With regard to the other models though, one can utilize MHI and Garrett parts to create a hybrid within reason.

Now you should have a solid foundation to research which type, brand, and size of turbo will suit your needs. Remember that research is critical and you shouldn’t choose the “turbo of the month” as many seem to do. A 500HP capable turbo can be an absolute dog to drive in stop and go traffic. Likewise, a turbo with Insta-Spool® will not net you an 11 second time slip. Many of the features here are described as smaller = less power, fast boost and bigger = more power, slow boost. The same rules apply to turbos overall. The goal is to find a happy medium which will meet most of your desires.

This article should not your sole source of information though and you should consider the following additional research activities when considering an upgrade:

a. Compressor map plotting and interpretation (MHI and Garrett particularly)

b. Your tuner’s advice and experience

c. Your turbo vendor’s advice and experience

d. Corky Bell’s book "Maximum Boost: Design, Testing, and Installing Turbocharger Systems". Considered by many to be the Alpha and Omega of turbo information.